Which series u joint has the greatest torque capacity – In the realm of universal joints, the question of which series reigns supreme in terms of torque capacity takes center stage. This article delves into the intricacies of torque capacity, exploring the factors that influence it and examining the design considerations, material selection, and testing methods that contribute to exceptional torque handling capabilities.

As we embark on this exploration, we will uncover the advantages and disadvantages of various universal joint types, shedding light on the design features that enhance torque capacity. Furthermore, we will delve into the significance of material selection, examining the properties of commonly used materials and their impact on torque performance.

Joint Torque Capacity Overview

In the context of universal joints, torque capacity refers to the maximum amount of torque that the joint can transmit without failing.

Factors influencing torque capacity include material, design, and size.

Types of Universal Joints: Which Series U Joint Has The Greatest Torque Capacity

| Type | Torque Capacity | Advantages | Disadvantages |

|---|---|---|---|

| Single U-Joint | Moderate | Simple design, low cost | Limited angle of operation, lower torque capacity than other types |

| Double U-Joint | High | Higher torque capacity than single U-joint, allows for larger angles of operation | More complex design, higher cost |

| CV Joint | Highest | Constant velocity operation, high torque capacity, allows for extreme angles of operation | More complex design, higher cost than U-joints |

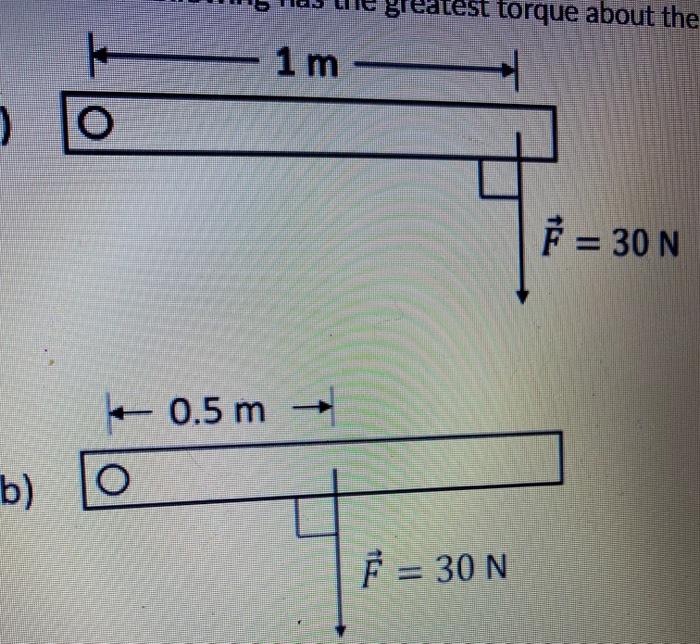

Design Considerations for High Torque Capacity

- Cross-sectional shape:A larger cross-sectional area increases torque capacity.

- Bearing size and type:Larger bearings and needle bearings provide higher torque capacity.

- Lubrication systems:Proper lubrication reduces friction and wear, enhancing torque capacity.

- Steel:High strength, good torque capacity, but prone to corrosion.

- Aluminum:Lightweight, good torque capacity, but less durable than steel.

- Composites:High strength-to-weight ratio, good torque capacity, but more expensive.

- Static torque testing:Measures the maximum torque that the joint can withstand without failing.

- Dynamic torque testing:Evaluates the joint’s performance under varying loads and speeds.

- Automotive drivelines:Transmitting torque from the engine to the wheels.

- Industrial machinery:Connecting shafts and gears in heavy-duty equipment.

- Aerospace:Providing power transmission in aircraft engines.

Material Selection and Properties, Which series u joint has the greatest torque capacity

Material selection plays a crucial role in torque capacity.

Common materials used in universal joints include:

Testing and Evaluation Methods

Torque capacity is determined through various testing methods, including:

Applications and Case Studies

High torque capacity universal joints are used in various applications, such as:

Top FAQs

What is torque capacity in the context of universal joints?

Torque capacity refers to the maximum amount of torque that a universal joint can transmit without failure.

Which factors influence the torque capacity of a universal joint?

Factors influencing torque capacity include material, design, size, cross-sectional shape, bearing size and type, and lubrication systems.

What are the advantages and disadvantages of different types of universal joints?

Single universal joints offer simplicity and low cost but have limited torque capacity. Double universal joints provide higher torque capacity but introduce vibration issues. CV joints offer high torque capacity and smooth operation but are more complex and expensive.

How does material selection impact torque capacity?

Materials with higher strength and hardness, such as steel and certain alloys, can withstand higher torque loads.

What testing methods are used to determine torque capacity?

Testing methods include static torque testing, dynamic torque testing, and fatigue testing.